Auomotive Marking Application

The demand for marking and engraving products in the manufacturing industry is increasing like crazy. The manufacturers are frequently hunting for better and convenient methods to mark and engrave their products.

HeatSign offers the best marking solutions by maintaining high product standards, avoiding any counterfeiting, and checking that suppliers maintain the quality standards.

The various types of marking and engraving processes including the dot peen, laser marking, and inkjet have their individual significance in various industries.

Marking technology in Automotive Industry

Marking technologies have the maximum advantage in the automotive industry as this industry recognized the importance and usage of marking solutions earlier than other industries.

Automotive parts are marked for several reasons including traceability, identification, compilation with the international standards, and for automated marking and reading.

Automotive industry requires very careful marking and engraving solutions which makes it very sensitive and prone to marking mistakes. Keeping this in mind, HeatSign has introduced such marking technology that flawlessly marks the automotive parts without compromising with the quality and ensures overall safety to the automotive vehicles.

You can mark your automotive parts through different types of marking process including laser marking, dot peen marking, or inkjet printing.

The markings are required by both the manufacturer and the car owner.

However, the manufacturer needs the larger share of this industrial marking as they are required to carefully mark even the smallest parts of the machine due to legal and industrial policies.

The car owners usually mark their vehicles for identification purposes.

List of the parts marked by the manufacturer:

Engine Components

The engine of an automotive vehicle comprises a variety of metals and alloys including gears, pistons, axles, engine blocks, cylinders, crankshafts, and camshafts. These parts are very difficult to mark as one rooky mistake can raise legal questions and enquiries.

Therefore, manufacturers want markings that will survive the entire lifecycle of the car while still achieving optimum efficiency and strength. The markings have to be permanent and legible.

This is because most of these parts are exposed to high degrees of heat and pressure. It is, therefore, necessary that they use marks that do not degrade under these conditions. The best technology for this type of marking is high-power laser etching.

Fuel supply system

The marking components in the fuel supply system includes the fuel pump, air cleaner, radiator, and fuel injection system. You need to keep one important thing in mind that the materials that make these fuel supply parts are different from the vehicle they make. It is necessary to understand their different requirements and use laser markings on solid plastics while dot peen marking for metals.

Gearcase

The function of the gearcase which is a non-moving part is to hold the components of the gearbox. The gear casing production uses materials like steel alloys which makes the dot peen marking, or the fiber laser marking the smartest choice for marking and engraving the gearcase.

Car chassis

The car chassis includes car frames, doors, and body panels. They are static parts that are majorly made of metal bars and sheets. This makes the dot peen marking a perfect choice to mark these parts.

You can buy cheaper marking equipment which is rising from Chinese companies like Huapu, HeatSign, and the list goes on.

Why choose HeatSign for your Automotive VIN marking solutions?

User-friendly: HeatSign designs such automotive VIN marking machines which do not require particular technical skills. The integrated structure of the marking machines are easy to understand and convenient to operate.

Latest technology: In today’s challenging industrial world HeatSign stands out in the market as it offers newest technology for its users which does not require much maintenance and can work for long hours.

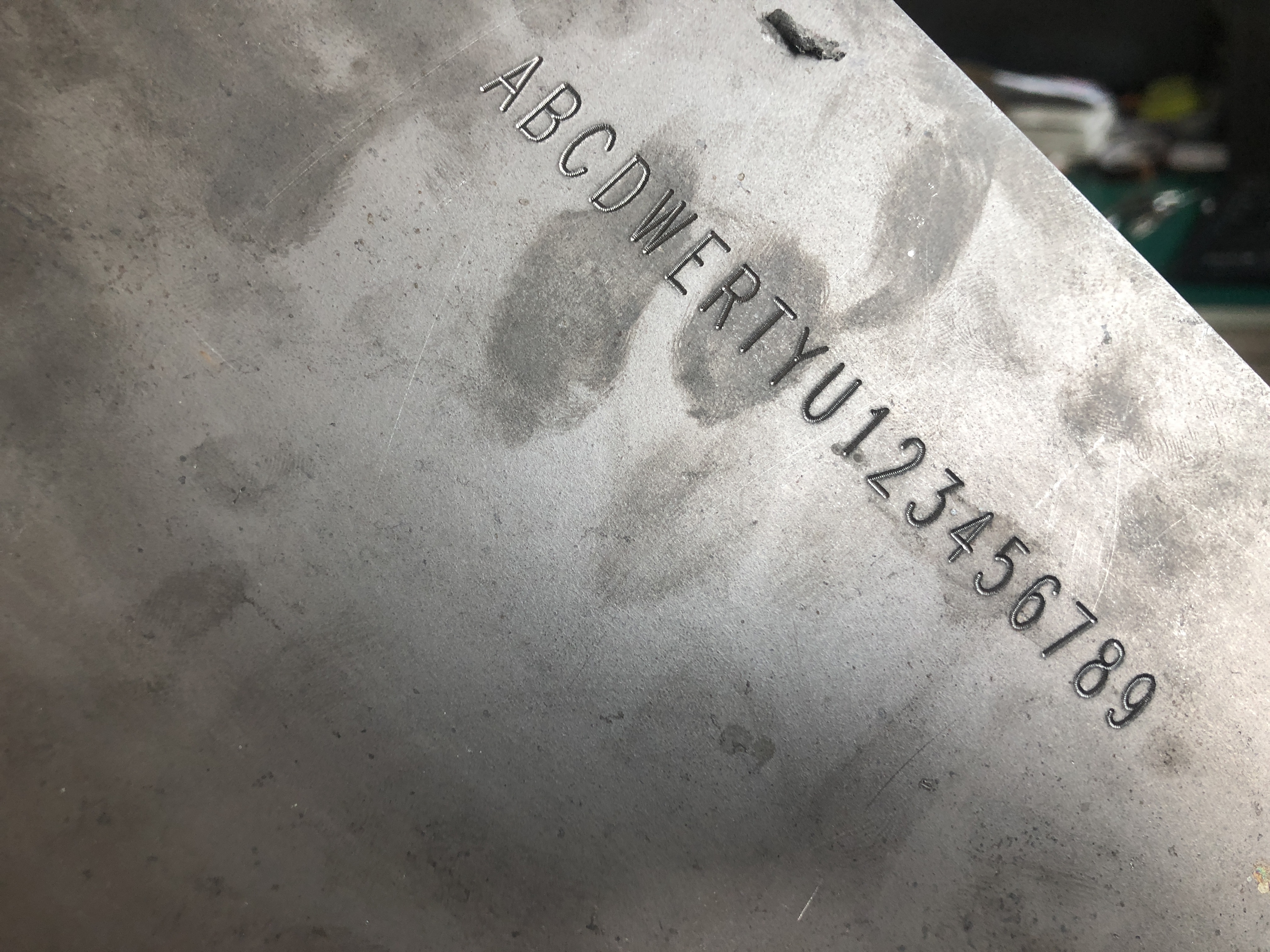

Marking Result: The marking result produced by the HeatSign automotive VIN marking machine is remarkable and guarantees permanent marking on the materials. Such markings are not damaged by outer sources like the temperature, heat, gas, pollution, oils, vapors, and so on.

The marking result will remain intact and shiny like day one.

If you are interested in buying this amazing automotive VIN marking technology, then feel free to contact us. We are more than happy to assist and guide you about the different marking solutions based on your marking requirements.